- Home

- Design and Customization

- Manufacturing

- Custom Acrylic/Plastic Fabrication

Custom Acrylic/Plastic Fabrication

Acrylic Display Fabrication / Product Specialties:

- Acrylic Photo/Picture Frames

- Acrylic Poster Frames

- Acrylic Poster and Sign Holders

- Acrylic Literature/Brochure Holders

- Acrylic Dispenser and Shelves

- Acrylic Display Stands and Easels

- Acrylic Book/Magazine Cases and Trays

- Acrylic Showcases and Display Cubes

- Acrylic POP Displays

- Acrylic Barriers and Screens

- Decorative Wall Panels

- Custom Acrylic Signs and Logos

- Custom Acrylic Fixture

Product Examples

Acrylic Custom Fabrication / Customization Process:

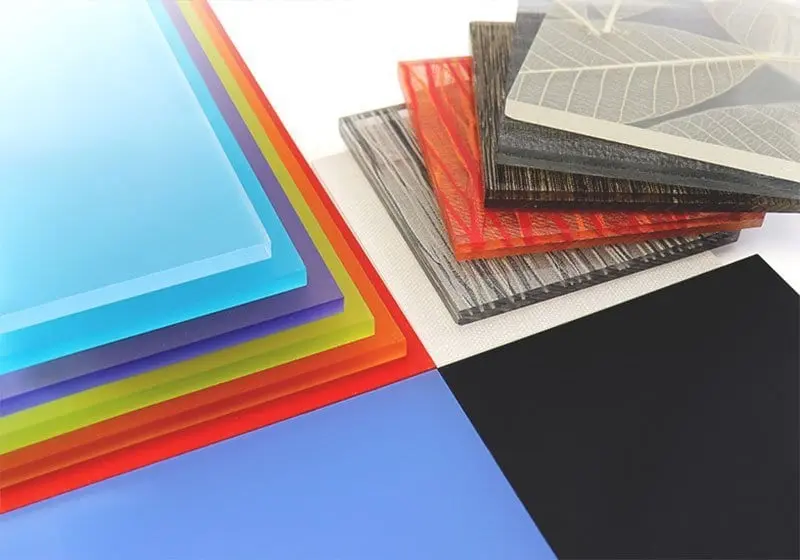

- Material Selection — Choosing the appropriate acrylic material based on thickness, color, opacity, finish, and type of material such as extruded or cast.

- Design Preparation — Process usually begins with a discussion in order to get a better understanding of customer’s requirements and design preferences.

- Sample Production — If required, after the design is finalized, we can produce a sample of the custom acrylic display product for our customers to review and approve.

- Fabrication and Assembly — Full production begins, custom acrylic display product is fabricated and assembled according to the approved design or sample.

- Quality Assurance — During production and after the custom display product is fabricated, it undergoes quality assurance checks to ensure that product meets all requirements and contains no defects.

- Shipping and Delivery — Upon completion, the custom acrylic display products are prepared for shipping to the customer’s specified location.

Acrylic Custom Fabrication / Range of Services:

Acrylic Laser Cutting is a significant process related to working with acrylic. We use highly effective and efficient laser cutting equipment that is suitable for cutting a wide range of acrylic thicknesses. Thin acrylic can be laser cut fairly effortlessly, while the thicker materials may require additional edge finishing. Our CO2 laser cutters can cut acrylics of any type up to 1/2” thick without loosing the edge quality and up to 1” thick which require additional edge finishing. Acrylic can be processed using a CNC router or a water jet as an alternative to laser cutting. CNC routers are capable of cutting and shaping acrylic with high precision, making them suitable for various display and signage applications. Water jet cutting can also be used to create clean and smooth cuts in acrylic material, offering advantages such as providing a uniform matte/frost edge surface, minimal material wastage, and the ability to cut through thicker materials without edge distortion. Laser, CNC routing, and water jet cutting are viable options for processing acrylic, and the choice between these methods depends on the specific requirements of the project, the design intricacy, the desired edge finish, or other important factors such as time and cost… more ❯

- Acrylic Laser Cutting and CNC Routing — This involves cutting the acrylic sheets to the required dimensions with a laser cutter or CNC router.

- Acrylic Folding and Bending — Acrylic sheets and ready parts are bent using heat or other processes to achieve the desired shape and form of the display products.

- Acrylic Gluing and Bonding — Various parts of the display products are assembled using solvent welding (cementing) or adhesive bonding.

- Acrylic Edge Polishing and Beveling — If necessary, the display product or parts undergo an edge finish using a diamond or flame polisher.

- Acrylic Parts Assembly and Finishing — Ready acrylic parts and display products can also be assembled using our specially designed fixtures and hardware.

- Acrylic Prototyping and Sampling — Involves the creation of preliminary models and samples of acrylic display products for testing and evaluation before full-scale production.